No products in the cart.

Eclipse AH MA

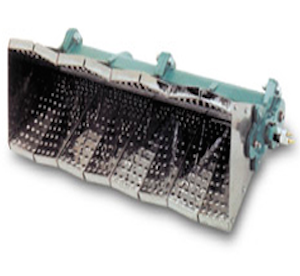

Current Version: 2.2 Type: Nozzle Mixing Number of Sizes: Modular Capacity Range: 1,200,000 Btu/hr/LF 1150 kW/m Turndown: 30:1 Max. Upstream Air Temperature: 450°F, 232°C Max. Downstream Air Temperature: 850°F, 454°C Fuels: Natural Gas, Propane, Butane Typical Applications: Make-up air heating Drying Processes Key Attributes: Robust, Reliable performance. Compact Modular design.Eclipse AirHeat V1

Current Version: 1.3 Type: Nozzle Mixing Number of Sizes: Modular Capacity Range: 1,000,000 (Btu/hr/LF) 961 (kW/m) Turndown: 40:1 Max. Process Temperature: 1500°F, 815°C Fuels: Natural Gas, Propane Typical Applications: Incinerators Dry-off nnd curing ovens Indirect air heating Textile Drying Food Processing/baking Ceramic Drying Key Attributes: Lowest CO emissions. Compact modular design. Robust, reliable performance. Industry Standard.Eclipse Furnnox

Current Version: 1.3 Type:Nozzle Mixing Number of Sizes:5 Capacity Range: 25,000 to 2,000,000 (Btu/hr) 73 to 586 (kW) Turndown:10:1 Max. Process Temperature:2800°F, 1540°C Fuels:Natural Gas,Propane, Butane Typical Applications: Galvanizing Furnaces Slot Type Forge Furnces Heat Treating Furnaces Key Attributes: Low NOx. Robust, Reliable performance Compact, Modular design.Eclipse Immersion Jet

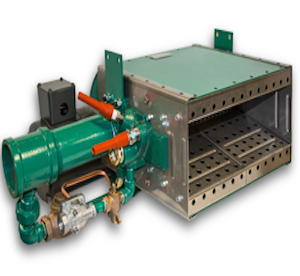

Current Version:2.6 Type:Nozzle Mixing Number of Sizes:5 (2", 3", 4", 6", 8") Capacity Range: 190,000 to 8,000,000 (Btu/hr) 56 to 2344 (kW) Turndown:7:1 minimum Max. Process Temperature:200 - 400°F, 93 - 204°C Fuels:Natural Gas, Propane, Butane Typical Applications: Wash and rinse tanks Dip Tanks Pickling Tanks Spray Washers Deep Fryers Salt Baths Quench Tanks Key Attributes: Up to 80% efficiency.Allows the use of smaller, lower cost tubes.Eclipse Ratio Air

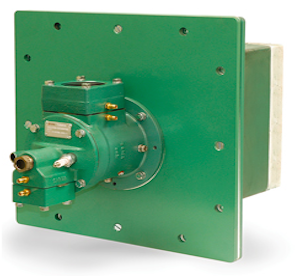

Current Version: 2.4 Type: Nozzle Mixing Number of Sizes: 9/11 Capacity Range: 150,000 to 20,000,000 (Btu/hr) 44 to 5860 (kW) Turndown: 30:1 Max. Process Temperature: 2800°F, 1538°C Fuels: Natural Gas, Propane, Butane Landfill Gas, Low BTU Gas Typical Applications: Dry-off and curing ovens Incinerators Indirect air heating Textile drying Food processing/baking Annealing Aluminum homogenizing Key Attributes: Easy set-up and operation. Modulating gas control, plus a wide range of low calorific value fuels.Eclipse Ratio Matic

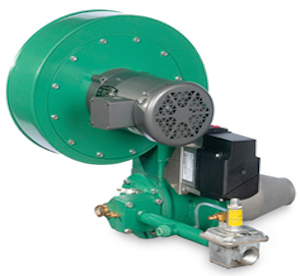

Current Version:5.2 Type:Nozzle Mixing Number of Sizes:14 Capacity Range: 500,000 to 30,000,000 (Btu/hr) 147 to 8785 (kW) Turndown:Up to 90:1 depending on burner size and chamber conditions Max. Process Temperature:1900°F, 1038°C Fuels:Natural Gas,Propane, Butane Typical Applications: Dry-off and curing ovens Incinerators Indirect air heating Textile drying Food processing/baking Annealing Aluminum homogenizing Key Attributes: Easy set-up. No gas adjustment with ratio control. Safety you can trust. Robust, reliable...Eclipse Therm Air

Current Version:2.3 Type:Nozzle Mixing Number of Sizes:9 Capacity Range: 150,000 to 5,000,000 (Btu/hr) 44 to 1467 (kW) Turndown:30:1 Max. Process Temperature:1900°F, 1038°C Fuels: Natural Gas, Propane, Butane, Landfill Gas, Low BTU Gas Typical Applications: Dry-off and curing ovens Incinerators Indirect air heating Textile drying Food processing/baking Annealing Aluminum homogenizing Key Attributes: Easy set-up and operation. Modulating gas control, plus a wide range of low calorific value fuels.Eclipse ThermJet

Current Version: 2.7 Type: Nozzle Mixing Number of Sizes: 14 Capacity Range: 150,000 to 20,000,000 (Btu/hr) 44 to 5860 (kW) Turndown: 50:1 Max. Process Temperature: 2800°F, 1540°C Fuels: Natural Gas,Propane, Butane Typical Applications: Tempering Furnaces Hardening Furnaces Reheating Furnaces Fluidized Bed Dryers Thermal Oxidizers Non-Ferrous Melting Ladle/Tundish, Glass Lehrs Environmental Applications Preheated Air Key Attributes: Easy set-up with built-in metering. Best high velocity burner on the market. Robust, reliable performance.Eclipse Winnox

Current Version: 2.4 Type: Nozzle Mixing Number of Sizes: 8 Capacity Range: 550,000 to 12,500,000 (Btu/hr) 161 to 3660 (kW) Turndown: 7:1 up to 17:1, consult the specific datasheet for the actual turndown for each model Max. Process Temperature: 1800°F, 982°C Fuels: Natural Gas, Propane, Butane Typical Applications: Dry-off and curing ovens Incinerators Indirect air heating Textile drying Food processing/baking Annealing Aluminum homogenizing Key Attributes: Robust, reliable performance. 5 - 20 ppm NOx emissions. Simple...Showing all 9 results